See below for answers to our most common questions

What is an expansion joint? Can you install it? Find answers to these questions and more below. Or reach out to the team for something more specific.

Expansion Joint Concepts

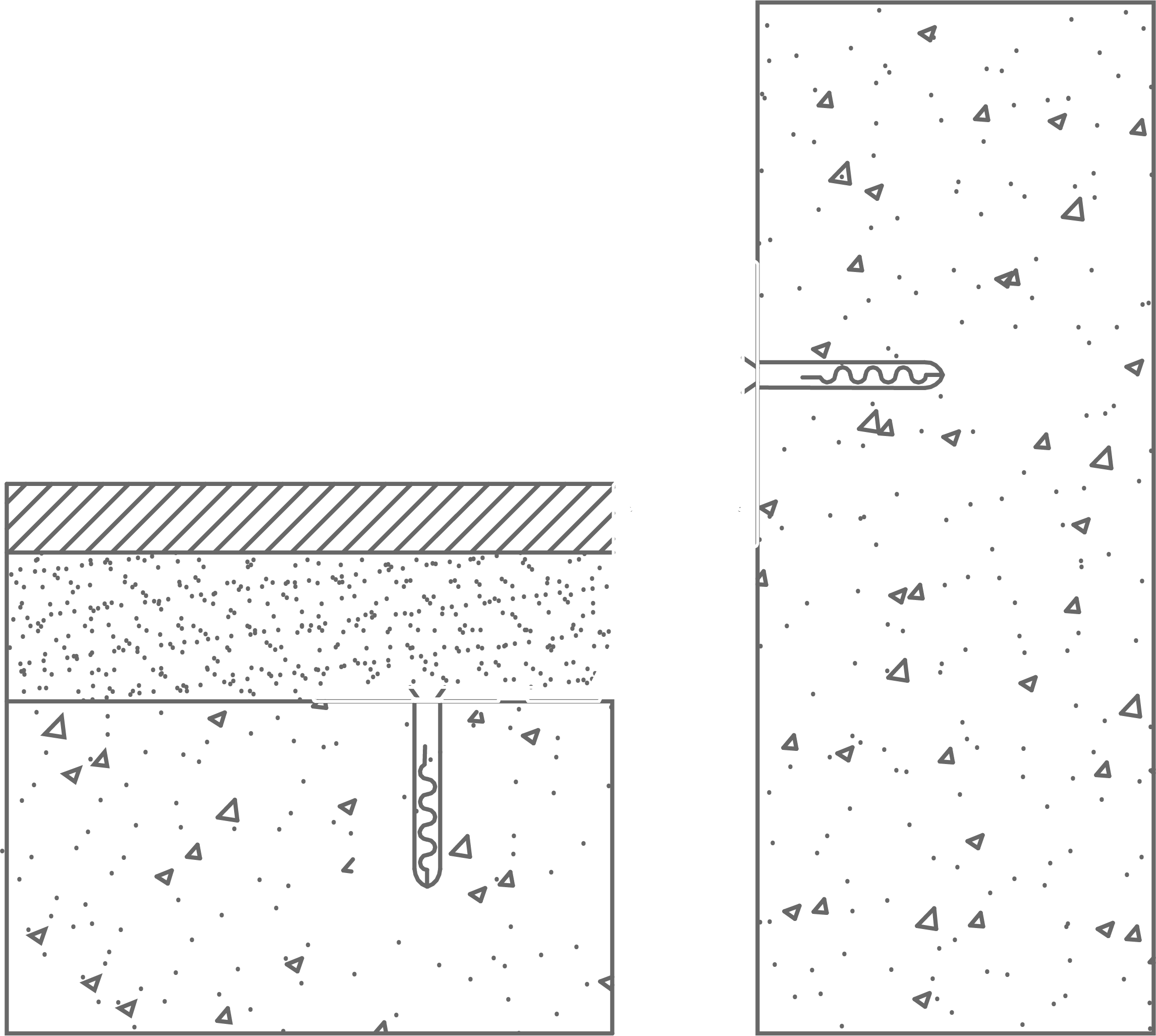

What is an expansion joint?

Expansion joint is an opening within a structure, at predetermined locations, designed to absorb structural movements:

- Thermal – horizontal movement from temperature changes

- Seismic – horizontal, vertical, or shear from earthquake activity

- Wind Load – horizontal/shear movement from strong winds

What are movement ratings?

Movement rating categorizes anticipated horizontal change in a joint. A 4” joint with ±2” movement is rated +/- 50%. Thermal joints = +/- 10–25%, seismic = +/- 50%.

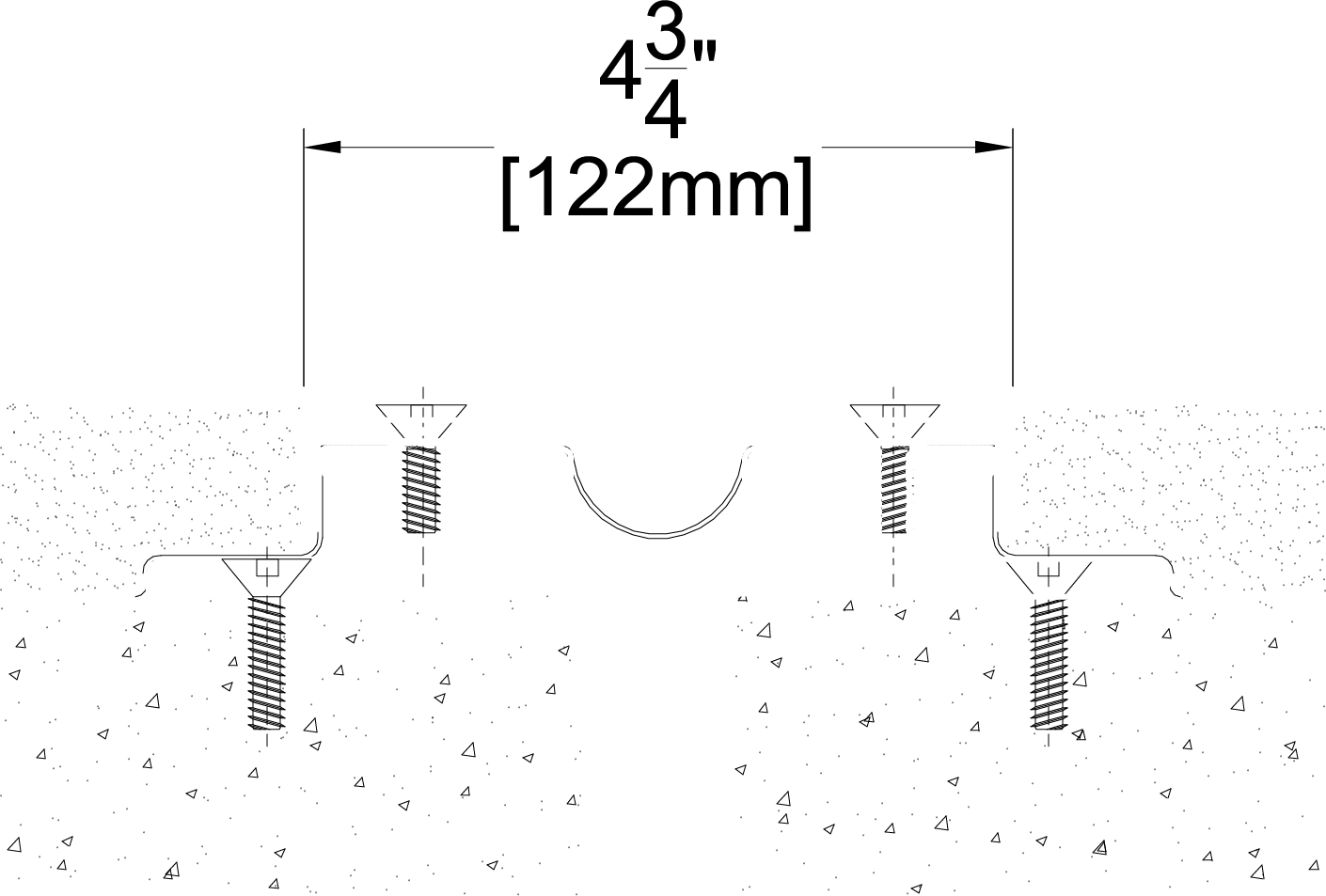

What is nominal joint width?

The design width of an opening at median temperature. It may vary at installation due to thermal conditions.

What is an expansion joint system?

An expansion joint system bridges an opening with a plate, insert, or engineered solution to:

- Fit opening size

- Absorb movement

- Match surface finish

- Support load (floor systems)

What type of movement is required?

Assess for thermal, seismic, sway, or shear. Seismic Guys offers covers to handle 100% movement in all directions.

What size joint is called for?

Typically defined by the engineer. Seismic areas use joints > 4”. Non-seismic: 1–4”.

What are the required minimum & maximum joint openings?

Depends on the engineer’s spec. Always confirm if they’re referring to width or total movement.

Product Selection & Specs

How do I select architectural expansion joint systems?

Choose based on:

- Function – e.g., location (floor, wall, ceiling), load rating, interior/exterior

- Form – e.g., visual appearance, concealed or exposed

Is there any standard test methods applicable to architectural expansion joint systems?

Yes: ASTM-E1399-97 is a standard for cyclic movement and measuring joint width.

Is loading important?

Absolutely. Loads exceeding design may cause failure, posing risks. Check load ratings and specs.

What surface do I start with?

Start with floor covers — they impact user safety and mobility. Use flush covers for loads >500 lbs.

Where do I find matching wall & ceiling joints?

Seismic Guys floor covers have coordinating wall and ceiling options.

What should the cover look like?

If a hidden solution is important, Prospec offers unobtrusive designs. Visible options available too.

Does my joint require a fire barrier?

Yes — if in a fire-rated area, a fire barrier must match the wall’s rating and span floor to floor.

Weather integrity and expansion joint covers?

Ensure exterior wall covers are watertight. Prospec offers factory-formed transitions to prevent leaks.

Fire Barriers

Where is a fire barrier used and why?

Fire barriers are used in floor and wall joints in fire-rated zones to:

- Prevent fire/smoke transfer

- Maintain cold-side temperature during a fire

Types:

- Mineral wool + Fire sealant

- Ceramic blanket

What are fire rating standards?

Common standards:

- UL-2079

- ASTM E-1966

- ASTM E-1399

- ASTM E-119

Entrance Mats

Can you replace carpet inserts?

Yes — for Prospec mats, we can replace inserts.

Do you provide a drain pan?

No.

What size modules does the mat come in?

Refer to the product’s PDF data sheet for max module sizes.

If replacing a mat, do I also need to buy a new frame?

Most likely not.

How thick/high should the entrance mat be?

Depends on the mat type and application.

What should be the minimum dimension of an entrance mat?

At least 4ft long; width varies with traffic and layout.

Do you have a rollable mat?

Yes — our Rollet series are rollable for easy maintenance.

What sizes do the Rollet series mats come in?

Custom-made to your specifications.

What is the difference between a welcome mat frame and a ramp frame?

Welcome mat frames sit in a mat well; ramp frames are used when there’s no mat well.

Can you manufacture custom-shaped mats (e.g., round, parallelogram)?

Yes.

Installation

Do you provide installation service?

Yes, we provide professional installation for all our systems. Our experienced team ensures every product is installed accurately and in accordance with specifications, delivering a high-quality finish and long-term performance.

Is there a minimum quantity to buy products?

Yes, for most expansion joint covers (EJC), a minimum order of 10 feet (approximately 3 meters) is required.

What is the standard length of profile?

Our profiles are typically supplied in standard 10-foot (3-meter) lengths. Custom sizing may be available upon request, MOQs may apply.

Orders & Logistics

How to get a quotation?

To request a quote, send us an email with the following details:

-

Your company name and contact information

-

Project name and location

-

Product name(s) and quantities required

We’ll respond promptly with a detailed quotation tailored to your needs.

Or use our contact form

How do I place an order?

To place an order, please email us a formal purchase order along with proof of payment. Our team will confirm your order and begin processing.

What is the lead time?

For larger orders our standard production lead time is approximately 4–6 weeks, depending on the product and order volume. Please contact us for timeframes specific to your project.

Do you offer express production service?

Yes, we offer express production on most items. This service is subject to availability and incurs an additional fee.

Do you offer a delivery service?

Yes, we work with trusted third-party freight providers to arrange delivery. Freight charges are calculated based on order size and destination.

Do you offer warranty on your products?

Yes, our products come with a 3-year manufacturer’s warranty and two years workmanship warranty.

What is your return policy?

Due to the customised nature of our products and services, we are unable to accept returns with the exception of a warranty claim. We encourage you to consult with our team during the specification stage to ensure accuracy.

What if the product received is damaged?

If your order arrives damaged or with a manufacturing defect, please notify us immediately. We will assess the issue and arrange a suitable replacement in line with our warranty terms. For damages caused during freight there may be a delay while we resolve the issue.

Where are the products made and manufactured?

All of our products are proudly manufactured in Canada, following strict quality control and performance standards.